Introduction Cleanroom Plane Layout

Introduction Cleanroom Plane Layout

April 11, 2024

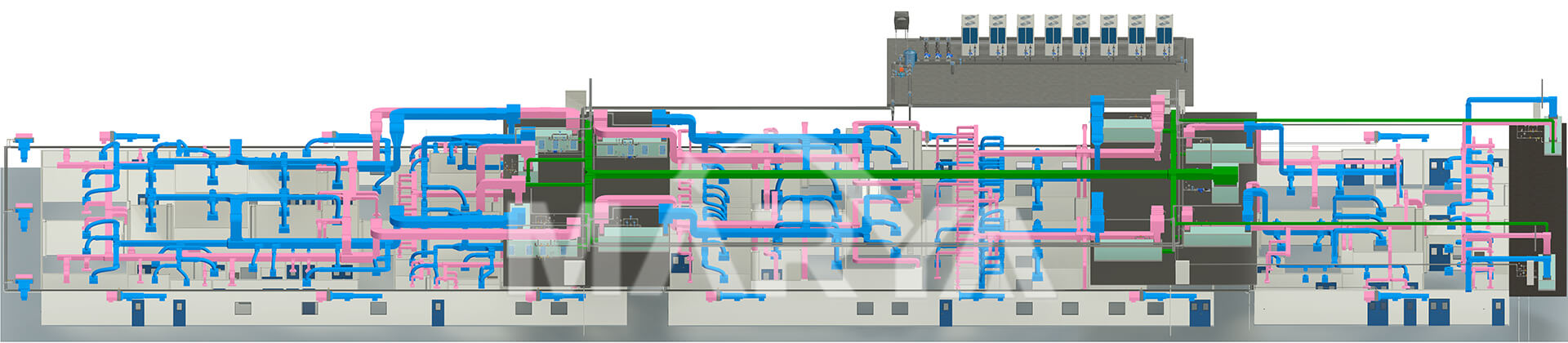

1. Plane Layout

Wrap-around verandah: The verandah can have windows or no windows, and is used for visiting and placing some equipment. Some have on-duty heating inside the verandah. Exterior windows must be double-seal windows.

Inner corridor type: The cleanroom is located on the periphery and the corridor is located inside. The cleanliness level of this corridor is generally higher, even the same level as the cleanroom.Two-end type: the clean area is located on one side, and the quasi-clean and auxiliary rooms are located on the other side.

Core type: To save land and shorten pipelines, the clean area can be the core, surrounded by various auxiliary rooms and hidden pipeline spaces. This method avoids the impact of outdoor climate on the clean area and reduces cold and heat energy. consumption, conducive to energy saving.

2. Personal Purification Route

To minimize the pollution caused by human activities during operation, personnel must change clean clothes and shower, bathe, and disinfect before entering the clean area. These measures are called "personal purification".

The room where clean clothes are changed in the cleanroom should be provided with air, and positive pressure should be maintained for other rooms such as the entrance side. A slight positive pressure should be maintained for toilets and showers, while negative pressure should be maintained for toilets and showers.

3. Material purification route

Various objects must be purified before being sent to the clean area, referred to as "object cleaning".

The material purification route and the human purification route should be separated. If materials and personnel can only enter the cleanroom at the same place, they must also enter through separate doors, and the materials must first undergo rough purification treatment.

For situations where the production line is not strong, an intermediate warehouse can be set up in the middle of the material route.

If the production line is very strong, a straight-through material route is adopted, and sometimes multiple purification and transfer facilities are required in the middle of the straight-through route.

Regarding system design, many raw particles will be blown off during the rough purification and fine purification stages of the cleanroom, so negative pressure or zero pressure should be maintained in the relatively clean area. If the risk of contamination is high, negative pressure should also be maintained in the direction of the entrance.

4. Pipeline Organization

The pipelines in the cleanroom are very complex, so these pipelines are organized in a concealed manner. The specific concealment organization methods are as follows.

a. Technology mezzanine

(1) Top technical mezzanine. In this kind of mezzanine, the supply and return air ducts generally have the largest cross-sections, so they are the first objects to be considered in the mezzanine. It is generally placed at the top of the mezzanine, and electrical pipelines are placed below it. When the bottom plate of this kind of mezzanine can bear a certain weight, filters and exhaust equipment can be installed on it.

(2) Room technical mezzanine. Compared with only the top mezzanine, this method can reduce the wiring and height of the mezzanine and can save the technical duct required for the return air duct to return to the upper mezzanine. The lower aisle can also be equipped with a return air fan, power equipment, power distribution, etc. The upper aisle of a certain floor of cleanroom can also serve as the lower aisle of the upper floor.

b. Technical tunnel (wall)

The horizontal pipelines in the upper and lower mezzanines generally need to be turned into vertical pipelines, and the hidden space where these vertical pipelines are located is the technical tunnel. Technical tunnels can also be used to place some auxiliary equipment that is not suitable for cleanrooms and can even be used as general return air ducts or static pressure boxes, and some can be installed with light tube radiators.

Since most of these technical tunnels (walls) use lightweight partitions, they can be easily adjusted when the process is adjusted.

c. technology shaft

If technical tunnels (walls) often do not cross floors, technical shafts are used when they need to cross floors and are often permanent as part of the building structure.

Since the technical shaft connects the various floors, to prevent fire, after the internal pipelines are installed, the interlayers must be sealed with materials with a fire-resistance rating not lower than the floor slabs. The maintenance work is carried out in layers, and the maintenance doors must be equipped with fire doors.

Regardless of the technical mezzanine, technical tunnel, or technical shaft, when it is directly used as an air duct, its inner surface must be treated according to the requirements of the inner surface of the cleanroom.

5. Computer room location

It is best to locate the air-conditioning machine room close to a cleanroom that requires a large air supply volume and strives to keep the air duct lines as short as possible. However, to prevent noise and vibration, it is required to separate the cleanroom from the machine room. Both aspects are considered. The separation methods include:

a. There are several ways to construct separation:

(1) Settlement joint isolation type. Make the settlement joint pass between the cleanroom and the machine room to play a dividing role.

(2) Wall-mounted partition type. If the computer room is close to the cleanroom, it does not share a common partition wall, but each has its partition wall, and there is a gap of a certain width between the two partition walls.

(3) Auxiliary room separated type. An auxiliary room is set up between the clean room and the machine room to act as a buffer.

b. Dispersion methods are divided into the following types:

(1) Dispersion method on the roof or ceiling: Nowadays, it is common to place the computer room on the uppermost roof to keep it away from the cleanroom below. However, the lower floor of the roof is best set as an auxiliary or management room layer, or as a technical mezzanine.

(2) Underground decentralized type: The computer room is located in the basement.

c. Independent construction method. Set up a separate computer room outside the cleanroom building, but it is best to be very close to the cleanroom. The computer room should pay attention to vibration and sound insulation issues, and all floors should be waterproofed and drainage measures should be provided.

Vibration isolation: Anti-vibration treatment should be provided on the brackets and bases of fans, motors, water pumps, etc. at the vibration source. If necessary, the equipment should be installed on a concrete plate, and then anti-vibration materials should be used to support the plate. The weight of the plate should be 2 to 3 times the total weight of the equipment.

Sound insulation: In addition to installing a muffler on the system, large computer rooms can consider attaching materials with certain sound absorption properties to the walls. Sound insulation doors should be installed. Do not open the door on the partition wall from the clean area.

6. Safe evacuation

Since the cleanroom is a highly airtight building, its safe evacuation has become a very important and prominent issue, which is also closely related to the setting of the purification air conditioning system. Generally, the following points should be noted:

a. There should be at least 2 safety exits in the fire prevention area or clean area of each production floor. Only when the area is less than 50 square meters and the number of people is less than 5, only one safety exit is allowed.

b. Clean entrances for people should not be used as evacuation exits. Because the routes for clearing people are often circuitous, it is very difficult to ask people to run outside quickly once the fireworks are over.

c. The air shower room cannot be used as a general access channel. Since this kind of door is often two-leaf interlocking or automatic, once it fails, it will greatly affect evacuation. Therefore, a bypass door is generally installed in the air shower room. It must be used when there are more than 5 workers. Normally, when staff leave the cleanroom, they should not go through the shower room but through the bypass door.

d. Taking into account the need to maintain indoor pressure conditions, the doors of each cleanroom in the clean area should be opened toward the room with high pressure, because the door must be pressed tightly by pressure, which is contrary to the requirements for safe evacuation. To take into account the two requirements of daily cleanliness and emergency evacuation, it is stipulated that the door between the clean area and the non-clean area, and the door between the clean area and the outdoors are treated as safety evacuation doors, and their opening directions should all face the evacuation direction. Of course, the same is true for individual security doors.

Next:

None

Knowledge Center